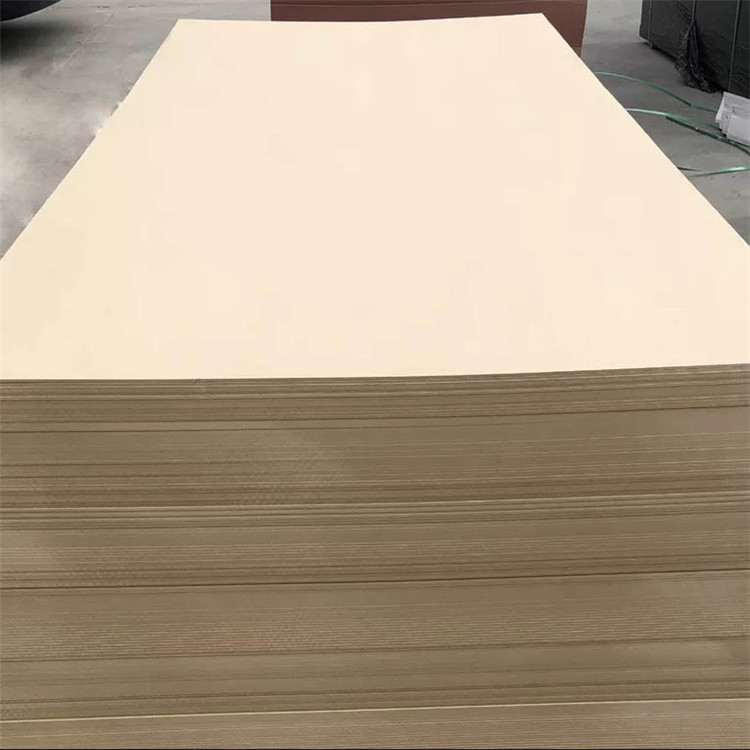

| Product name | Raw MDF ,Plain MDF |

| Face /back | Plain or Melamine Paper/ HPL /PVC /Leather / etc ( one side or both side melamine faced ) |

| Core material | wood fiber (poplar, pine,birch or combi) |

| Size | 1220×2440, or as request |

| Thickness | 2-25mm (2.7mm,3mm,6mm, 9mm ,12mm ,15mm,18mm or upon request) |

| Thickness tolerance | +/- 0.2mm-0.5mm |

| Glue | E0/E2/CARP P2 |

| Moisture | 8%-14% |

| Density | 600-840kg/M3 |

| Modulus of Elasticity | ≥2800Mpa |

| Static Bending Strength | ≥22Mpa |

| Application | Can be widely used in indoor |

| Packing | 1) Inner packing: Inside pallet is wrapped with a 0.20mm plastic bag 2) Outer packing: Pallets are covered with carton and then steel tapes for strengthening; |

wholesale price plain raw high density fiberboard MDF board

Shop high-quality wholesale price plain raw high density fiberboard (MDF) boards. As a factory, we guarantee superior products for your projects.

Request a QuotePRODUCTS DETAILS

Hot Products

White/red oak veneer fancy plywood

Brown film faced shutter formwork construction plywood

shandong birch faced plywood 3-35mm poplar/eucalyptus core plywood for furniture/construction

Hardwood plywood Triplay wooden tropical bintangor plywood

Poplar core okoume faced commercial plywood factory whosale price

PINE Oriented Strand Board OSB3 Flakeboards

Black walnut veneer fancy plywood

Factory wholesale OSB Waterproof oriented strand board 4x8 Panel for sheathing Roof materials

3mm Waterproof Laminated Okoume Marine Plywood sheet

wholesale price plain raw high density fiberboard MDF board

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours