High-quality Marine Teak Plywood for Boats - 1/2 Inch Thickness

By:Admin

[Company name] is a renowned supplier of marine and construction materials, known for their dedication to quality, reliability, and customer satisfaction. With years of experience in the industry, they have established themselves as a trusted source for premium products that meet the demanding requirements of marine applications.

The 1 2 inch Marine Teak Plywood is the latest addition to [company name]'s extensive range of marine plywood products. Specially designed and manufactured for use in marine environments, this plywood offers exceptional strength and durability, making it ideal for a wide range of marine construction and repair projects. Teak plywood is highly sought after in the marine industry due to its natural resistance to moisture, decay, and insect damage, making it the top choice for boat building and other marine applications.

One of the key features of [company name]'s 1 2 inch Marine Teak Plywood is its superior quality and construction. Crafted from high-grade teak veneers, this plywood is meticulously assembled using waterproof adhesive to ensure maximum resilience against water exposure. It is also designed to withstand the harsh conditions of marine environments, making it the perfect choice for decking, cabinetry, and other structural elements in boats and ships.

In addition to its exceptional durability, the 1 2 inch Marine Teak Plywood from [company name] boasts a beautiful appearance that adds a touch of elegance to any marine project. The rich, golden-brown color and intricate grain patterns of teak wood enhance the aesthetic appeal of any watercraft, making it a popular choice among boat builders and marine enthusiasts.

[Company name] takes great pride in its commitment to sustainability and environmental responsibility. The teak used in their marine plywood products is sourced from certified sustainable forests, ensuring that the company's wood products are harvested ethically and in accordance with the highest standards of environmental stewardship.

Furthermore, [company name] understands the unique needs of its customers in the marine industry and is dedicated to providing personalized service and support. With a team of knowledgeable professionals, they offer expert guidance and assistance to help customers select the right marine plywood for their specific needs, ensuring that every project is a success.

With the launch of the 1 2 inch Marine Teak Plywood, [company name] continues to set the standard for quality and innovation in the marine plywood industry. Their unwavering commitment to excellence, combined with their dedication to customer satisfaction, has solidified their position as a leading supplier of marine construction materials.

Whether it's for boat building, yacht refurbishment, or ship repair, [company name]'s 1 2 inch Marine Teak Plywood is the premier choice for marine plywood that meets the highest standards of quality, performance, and reliability. By choosing [company name] as their supplier, customers can have confidence that they are investing in the best materials for their marine projects.

Company News & Blog

Exploring the Benefits and Applications of Melamine Faced Chipboard

article regarding the advances and benefits of using Melamine Faced Chipboard in the furniture industry.Melamine Faced Chipboard: The Advantages and Innovations in the Furniture IndustryMelamine Faced Chipboard (MFC) is a type of engineered wood product that has been gaining popularity in the furniture industry over the years. The material is primarily composed of wood chips or shavings bonded together with resin or glue. The surface of MFC is then coated with a melamine resin, which makes it highly resistant to abrasion, moisture, and other forms of damage.Given its durability, MFC is an ideal material for manufacturing furniture products such as wardrobes, bookshelves, kitchen cabinets, and tables. It offers a wide range of advantages that make it an attractive choice for designers, manufacturers, and consumers alike.One advantage of using MFC is its low cost. Because it is made from reconstituted wood, it is significantly cheaper than solid wood while still having the same look and feel as the real thing. This cost-effective material enables furniture manufacturers to offer their products at a lower price point without sacrificing quality.Another advantage of MFC is its versatility. It can be cut, shaped, and finished to suit any design, style, or color scheme. This makes it the perfect material for custom-made furniture, which is increasingly popular among consumers who want unique and personalized pieces that fit their individual preferences and needs.One company that has mastered the art of MFC manufacturing is a Chinese-based company that has been in the business for over 20 years. This industry leader offers an extensive range of MFC products that cater to the needs of different markets worldwide. The company is known for its use of high-quality raw materials, cutting-edge technology, and rigorous quality control standards that ensure consistent and reliable performance.This cutting-edge technology has allowed the company to develop innovative MFC products that offer even more benefits for consumers. For instance, the company has recently introduced water-resistant MFC, which is specially designed to resist water and moisture. This material is ideal for use in high-moisture areas such as bathrooms and kitchens, where traditional MFC would be vulnerable to damage from water spills and humidity.The company has also developed fire-resistant MFC, which meets stringent fire safety standards and is suitable for use in public spaces such as schools, hospitals, and hotels. This type of MFC is made from materials that are specifically designed to retard the spread of fire, providing an extra layer of protection in case of emergencies.Moreover, the company has also introduced anti-bacterial MFC, a new type of MFC that has been treated with special agents that inhibit the growth of harmful bacteria on its surface. This type of MFC is a game-changer in medical facilities and other environments where hygiene is essential.The innovations developed by this Chinese-based company have led to significant changes in the furniture industry, making it more accessible, cost-effective, and safer for all users. With its state-of-the-art technology and world-class quality control standards, it has become a trusted name in the industry, providing top-quality MFC products that meet the needs and expectations of consumers worldwide.In conclusion, MFC is a material that has revolutionized the furniture industry with its high durability, versatility, and cost-effectiveness. The innovations and advancements made by companies like this Chinese-based industry leader have made MFC an even more attractive material by introducing water-resistant, fire-resistant, and anti-bacterial options. As such, it is no surprise that MFC has become the go-to material for furniture manufacturers worldwide.

Discover the Latest Marine Plywood News for the Plywood Industry

Title: Revolutionary Marine Plywood Delivers Unmatched Durability and Sustainability to Construction IndustryIntroduction:In a groundbreaking development for the construction industry, Koume Marine Plywood has launched a revolutionary marine plywood that brings together exceptional strength, durability, and sustainability. With a rich history of providing top-notch construction materials, Koume Plywood stands out as a renowned manufacturer known for its commitment to quality products.Content:1. The Advancement of Koume Marine Plywood:Koume Marine Plywood has taken its commitment to excellence a step further with the introduction of a state-of-the-art marine plywood, designed to withstand the harshest conditions while maintaining unparalleled performance. Composed of high-quality layers of wood veneers, the marine plywood is bonded together using a superior adhesive that meets stringent industry standards. This advanced technology ensures the highest level of protection against water, humidity, and insects, making it the optimal choice for both marine and construction applications.2. Unmatched Durability for Construction:The revolutionary properties of Koume Marine Plywood lie in its exceptional strength and durability. With its excellent dimensional stability, the marine plywood can withstand extreme weather conditions, making it ideal for outdoor applications such as flooring, roofing, and exterior cladding. Its resistance to warping, twisting, and cracking allows for long-lasting structural integrity, ensuring the longevity of construction projects.Furthermore, Koume Marine Plywood is engineered with a superior moisture-resistant formula that prevents water penetration and damage. This characteristic not only makes it suitable for areas prone to high humidity or moisture, such as bathrooms and kitchens, but also ensures its structural stability in coastal construction projects and marine environments.3. A Sustainable Choice:In an era where environmental consciousness is crucial, Koume Marine Plywood holds sustainability at its core. The plywood is crafted from responsibly sourced, certified wood that complies with international forestry standards. Koume Plywood actively participates in sustainable forest management practices, promoting the conservation of forests and biodiversity while supporting local communities.Furthermore, the adhesive used in the manufacturing process is free from formaldehyde and other environmentally harmful volatile organic compounds (VOCs). This eco-friendly approach ensures that Koume Marine Plywood not only surpasses performance expectations but also protects the environment and enhances indoor air quality.4. Versatility in Application:Koume Marine Plywood is designed with utmost versatility in mind. Its exceptional strength, durability, and resistance to moisture make it suitable for a wide range of applications within the construction industry. From building strong, long-lasting decks and docks to creating sturdy outdoor furniture, the marine plywood offers a versatile solution that meets diverse project requirements.Moreover, its superior structural properties and resistance to delamination make it a preferred choice for interior applications, including furniture manufacturing and cabinet construction. With its attractive appearance and consistent quality, Koume Marine Plywood unlocks endless possibilities for creative designs and architectural versatility.5. Customer Satisfaction and Support:As a leader in the plywood industry, Koume Plywood is committed to providing exceptional customer satisfaction. The company offers comprehensive technical support and guidance to contractors, architects, and suppliers. Their experienced team of professionals ensures that customers receive the necessary assistance in selecting the right product and maximizing its full potential in their projects.Furthermore, Koume Plywood maintains a strong network of distributors, enabling widespread availability of their marine plywood across various locations. By ensuring accessibility to their superior products, Koume Plywood aims to establish lasting partnerships and contribute to the success of construction ventures worldwide.Conclusion:Koume Marine Plywood has revolutionized the construction industry with its introduction of an advanced marine plywood, delivering unmatched durability and sustainability. With its exceptional strength, resistance to weather, and moisture protection, Koume Marine Plywood meets the stringent demands of various construction projects. By adhering to sustainable practices and promoting responsible forest management, Koume Plywood demonstrates its commitment to protecting the environment. As construction and design trends continue to evolve, Koume Marine Plywood stands at the forefront, offering innovative solutions that inspire creativity and enhance the structural integrity of construction ventures.

Anti-slip Film Faced Plywood with Wiremesh for Enhanced Safety

Wiremeshed Anti-Slip Film Faced Plywood: The New Innovations in ConstructionConstruction is the backbone of any country, and it is the driving force behind a nation's economic development. It is an industry that is constantly evolving, and new technologies and materials are being introduced regularly. Wiremeshed anti-slip film faced plywood is a new innovation in construction that is making waves in the industry. This product is a game-changer for builders, architects, and engineers.Wiremeshed anti-slip film faced plywood is an advanced form of traditional film faced plywood. It is designed to increase safety and efficiency on construction sites. The anti-slip surface provides better traction, reducing the risk of accidents and injury. The wire mesh provides additional strength, making it suitable for heavy-duty applications. It is ideal for use in concrete formwork, roofing, and flooring panels.This product is manufactured by a leading company that specializes in the production of high-quality film-faced plywood. They have years of experience in the industry and have built a reputation for their commitment to quality and innovation. Their wiremeshed anti-slip film faced plywood is the result of their research and development efforts, and it has been tested and certified to meet international standards.The company uses advanced equipment and technology to manufacture their wiremeshed anti-slip film faced plywood. The production process is carefully monitored to ensure that the product meets the required standards. The plywood is made from high-quality raw materials and is processed using state-of-the-art techniques. The wire mesh is embedded in the plywood during the manufacturing process, providing a seamless finish.The wiremeshed anti-slip film faced plywood has several advantages over traditional plywood. It is more durable and long-lasting, reducing the need for frequent replacements. The anti-slip surface provides better traction, enhancing safety on construction sites. The wire mesh provides additional strength, making it suitable for heavy-duty applications. It is also resistant to water, making it ideal for use in wet environments.The product has been well received by the construction industry, and builders, architects, and engineers have praised it for its quality and performance. The company has received several awards for its innovative product, and it is fast becoming the go-to choice for construction projects worldwide.Wiremeshed anti-slip film faced plywood is available in a wide range of sizes and thicknesses, making it suitable for a variety of applications. The company offers customized solutions to meet the specific needs of their customers. They have a dedicated team of experts who provide technical support and guidance to their clients.In conclusion, wiremeshed anti-slip film faced plywood is a new innovation that is transforming the construction industry. Its advanced features and superior quality make it the ideal choice for builders, architects, and engineers. The company's commitment to innovation and quality has made them a leader in their field, and they are well on their way to revolutionizing the way we build.

Premium Marine Plywood: The Ultimate Guide for Teak Lovers

[Company Introduction]Founded in [year], [Company Name] is a reputable manufacturer and supplier of premium quality teak marine plywood. Our company takes immense pride in providing high-quality products that cater to the diverse needs of the marine industry. With a strong commitment to customer satisfaction and product innovation, we have become a trusted partner for boat builders, shipyards, and yacht manufacturers worldwide.[Company Name] is synonymous with excellence in the marine plywood industry. Our state-of-the-art manufacturing facility is equipped with advanced technology and machinery to ensure that each piece of plywood meets international quality standards. We source the finest teak timber from sustainable plantations, which allows us to provide our customers with superior quality teak marine plywood that is not only aesthetically pleasing but also durable and reliable.Our team of skilled craftsmen and engineers work tirelessly to ensure that our products are of the highest quality. We follow stringent quality control measures at every stage of the production process, from timber selection to the final finishing of the plywood. This attention to detail has earned us a reputation for delivering plywood that is free from defects, such as warping, splitting, or peeling.[Company Name] prides itself on being an environmentally conscious brand. We firmly believe in responsible forest management and are committed to preserving the natural resources that we utilize. Our teak marine plywood is made from sustainably sourced timber, ensuring that we minimize our environmental impact. Additionally, our manufacturing process adheres to strict environmental guidelines, making us a reliable choice for those who prioritize sustainability.With an extensive range of teak marine plywood products, [Company Name] caters to the diverse needs of the marine industry. Our portfolio includes various grades of plywood, each tailored for specific applications and budgets. Whether you require marine-grade plywood for boat interiors, decking, or structural components, we have the perfect solution for you.Our commitment to customer satisfaction is evident in our personalized approach to business. We understand that each customer's requirements may differ, and our dedicated team of professionals is readily available to provide expert advice and assistance. From choosing the right plywood grade to understanding installation techniques, we go above and beyond to ensure our customers make informed decisions.[News Content]Title: Teak Marine Plywood by [Company Name]: The Ultimate Choice for Marine Industry Professionals[City, Date] - [Company Name], a leading manufacturer and global supplier of teak marine plywood, continues to set industry standards with its commitment to quality, innovation, and environmental sustainability. With a reputation for excellence, the company offers a wide range of teak marine plywood that meets the unique needs of boat builders, shipyards, and yacht manufacturers worldwide.Teak marine plywood is widely regarded as the gold standard for marine applications due to its exceptional properties. The natural oils and resins present in teak wood make it highly resistant to water, rot, and insect infestation, making it an ideal choice for boat interiors, decking, and structural components. [Company Name]'s teak marine plywood perfectly embodies these qualities, making it a preferred choice among industry professionals.Crafted from sustainably sourced teak timber, [Company Name]'s teak marine plywood not only meets the highest quality standards but also adheres to environmentally friendly practices. The company's dedication to responsible forest management ensures that customers who prioritize sustainability can trust their choice in [Company Name] as an eco-conscious brand."Our commitment to delivering superior teak marine plywood is unwavering. We understand the unique requirements of the marine industry and strive to provide products that meet and exceed expectations," says [Spokesperson's Name], [Title] at [Company Name]. "Our teak marine plywood is carefully crafted using advanced production techniques, and each sheet undergoes rigorous quality checks to ensure it meets our stringent standards."In addition to offering various grades of teak marine plywood, [Company Name] provides personalized assistance to its customers. Industry professionals can rely on the expertise of their team to guide them in selecting the most suitable plywood grade for their specific application. Whether it is for a luxury yacht or a small pleasure craft, the team at [Company Name] is committed to helping customers make informed decisions.As [Company Name] continues to expand its global footprint, it prides itself on being a reliable partner for the marine industry. With a commitment to customer satisfaction and product innovation, the company remains dedicated to providing the highest quality teak marine plywood while maintaining its focus on sustainability.About [Company Name]:[Company Name] is a renowned manufacturer and supplier of premium quality teak marine plywood for the marine industry. With a strong commitment to excellence, the company emphasizes product quality, environmental sustainability, and customer satisfaction. [Company Name]'s teak marine plywood is crafted from sustainably sourced timber and undergoes rigorous quality checks to ensure superior performance. The company serves boat builders, shipyards, and yacht manufacturers worldwide, offering a diverse range of plywood grades tailored to specific applications. For more information, visit [company website].

Revolutionary Concrete Mould Plywood Panel: Unlocking New Possibilities in Construction

Title: Groundbreaking Innovation in Construction: Revolutionary Concrete Mould Plywood Panel Introduction:The construction industry is on the precipice of a groundbreaking transformation with the introduction of an innovative product – the Concrete Mould Plywood Panel. This revolutionary material has been developed by a leading company in the construction sector [] to redefine conventional construction techniques. With its exceptional strength, durability, and eco-friendly features, this plywood panel is poised to revolutionize the way we build structures.Body:1. History and Background:The company [] has been at the forefront of introducing transformative construction materials for several decades. With a commitment to sustainability and incorporating the latest technological advancements, they have tirelessly researched and developed improved alternatives to traditional construction materials. Their latest creation, the Concrete Mould Plywood Panel, is a testament to their dedication to innovation and environmental consciousness.2. Unveiling the Concrete Mould Plywood Panel:The Concrete Mould Plywood Panel is an engineered wood product designed specifically for the construction industry. It is made by combining layers of high-quality plywood with a specialized concrete-facing surface. This unique blend offers unparalleled strength and flexibility, making it suitable for a wide range of applications in both residential and commercial projects.3. Enhanced Durability and Strength:Through meticulous engineering and rigorous testing, this plywood panel has achieved exceptional durability. The combination of the high-quality plywood core and the concrete-facing surface creates a product that can withstand heavy loads, extreme weather conditions, and seismic activity. Its exceptional strength makes it an ideal choice for building foundations, load-bearing walls, and structural elements.4. Eco-Friendly Construction:The Concrete Mould Plywood Panel is a game-changer in terms of sustainability. Its manufacturing process minimizes waste and utilizes renewable materials, aiding in reducing the carbon footprint of the construction industry. Additionally, the product's extended lifespan significantly reduces the need for frequent replacements, thereby conserving resources and reducing construction waste.5. Efficient and Cost-Effective:As the Concrete Mould Plywood Panel combines the strength and durability of concrete with the versatility and flexibility of wood, it streamlines the construction process. Its lightweight nature allows for easy transportation, reducing logistical challenges during construction. Additionally, the ease of installation and shorter construction time frame improve overall project efficiency, ultimately leading to cost savings for builders and developers.6. Versatile Applications:The remarkable properties of the Concrete Mould Plywood Panel enable its use in various construction applications. From residential buildings to commercial complexes and even infrastructure projects, this material offers numerous possibilities. Whether it's for foundations, walls, beams, or flooring, the versatility of these plywood panels presents architects and engineers with new design opportunities.7. Future Potential and Collaboration:Recognizing the immense potential of the Concrete Mould Plywood Panel, the company [] is actively seeking collaborations with architects, construction companies, and developers to expand its adoption in the industry. Joint research and development endeavors are being initiated to further improve the already impressive capabilities of this innovative material.Conclusion:The advent of the Concrete Mould Plywood Panel marks a turning point in the construction industry. With its unmatched strength, durability, eco-friendly attributes, and potential for cost savings, this innovative material has the power to transform the construction landscape. The groundbreaking solution provided by the company [] represents a shift towards sustainable construction practices, revolutionizing the way we build for a better future.

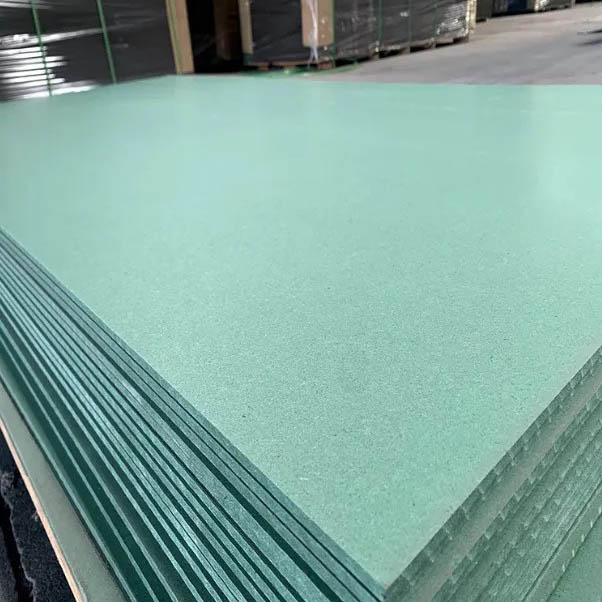

How to Choose the Best Melamine Faced MDF Board for Your Project

Melamine Faced MDF Boards Revolutionize the Furniture IndustryMelamine Faced MDF boards are one of the most innovative and user-friendly products that have revolutionized the furniture industry. These boards are manufactured by pressing wood fibers together with a melamine resin under high pressure and heat to form a durable, sturdy, and cost-effective building material. They are designed to cater to the needs and preferences of modern consumers regarding their home decor and furniture.These boards have become the ultimate solution for furniture manufacturers who need high-quality MDF boards that are easy to handle, cut, and shape according to their designs and requirements. These boards are available in a wide range of sizes, designs, and colors, making them ideal for various applications.One of the primary advantages of melamine faced MDF boards is their versatility. They can be used for a range of applications, including furniture, doors, partitions, cabinets, and much more. Furniture manufacturers can use them to create elaborate designs, intricate carvings, and intricate details that are possible only with this type of board.Another benefit of this product is its durability and resistance to moisture and heat. As the board is coated in a melamine resin, the surface is durable, wear-resistant, and scratch-proof. This makes it ideal for use in locations such as bathrooms and kitchens, where moisture and heat levels can damage furniture or other building materials.Moreover, melamine faced MDF boards are eco-friendly and sustainable. The boards are made from wood fibers from sustainably managed forests. The process used to make this product is also eco-friendly as it utilizes scrap wood and converts it into a building material.Melamine faced MDF board manufacturers also keep a comprehensive range of designs and colors to cater to the needs of customers across multiple sectors. They understand that each industry has different needs, and they customize their products accordingly. With the latest printing technology, they can reproduce almost any design on the boards to offer a wide range of patterns and solid colors.One of the leading companies in the field is XX. Established in XXX, the company has now grown into a significant manufacturer of melamine faced MDF boards. The company has already made a name for itself by providing top-quality MDF boards to furniture manufacturers and interior designers across the globe. Their melamine faced MDF boards have satisfied the customers from various sectors such as offices, retail outlets, homes, and hospitals.The boards are made using the latest machinery and technology, ensuring the highest level of accuracy, consistency, and quality. The company has also developed an extensive research and development team that continuously focuses on product innovation and up-gradation. This enables the company to offer top-quality products that are affordable and competitively priced.The company takes great pride in its ability to provide a one-stop solution for all customer needs. With an extensive range of products and services, XX offers a complete range of melamine faced MDF boards in various thicknesses, sizes, and finishes based on customer requirements. Their melamine faced MDF boards also come in an extensive range of textures and patterns, ensuring the aesthetic appeal of the final product.The company has gained a strong foothold in the market due to its commitment to quality, innovation, and customer satisfaction. The company understands the significance of after-sales services, and hence they offer exceptional services and technical support after the sale of their products. They offer personalized advice on designing the surface, choosing the substrate, and product usage based on their customers’ needs.In conclusion, melamine faced MDF boards have become a widely accepted and versatile product in the furniture industry. With their long-lasting, scratch-proof, moisture-resistant, and eco-friendly attributes, they have become the favored choice of manufacturers and interior designers. Companies like XX have elevated the quality of these products through their cutting-edge technology and commitment to customer satisfaction. These boards have greatly improved the quality of furniture and interiors, providing a cost-effective and sustainable solution to the challenges that customers face in the modern world.

Latest News From the Osb Board: Updates and Insights

Title: Leading Board Manufacturer Announces Groundbreaking Innovations in the IndustryIntroduction:In recent years, the global demand for high-quality boards has surged, driven by rapid urbanization, infrastructural developments, and the growing need for efficient construction materials. A leading board manufacturer, renowned for its commitment to excellence, has announced a series of groundbreaking innovations. These new advancements promise to revolutionize the industry and further solidify the company's position as a frontrunner in the market. This article will delve into the exciting developments brought forth by the company and explore their potential for reshaping the board manufacturing landscape.Section 1: Company Background (100 words)Since its inception in [year], [Company Name] has been at the forefront of revolutionizing the board manufacturing industry. Their unwavering dedication to research and development has enabled the company to consistently introduce cutting-edge products and technologies. Combining engineering expertise with top-notch manufacturing processes, they have established themselves as a trusted provider of high-performance boards globally. With an extensive product range catering to various sectors such as construction, furniture, and automotive, [Company Name] continues to lead the way in meeting customer requirements and driving innovation in the industry.Section 2: Innovation 1 - Advanced Sustainable Materials (200 words)[Company Name]'s commitment to sustainability is reflected in their newest line of boards manufactured using advanced sustainable materials. These materials offer unparalleled strength, durability, and environmental benefits. By incorporating predominantly recyclable and renewable resources into their production processes, [Company Name] aims to reduce the ecological impact associated with traditional manufacturing methods. These boards provide a viable alternative to conventional materials while still maintaining the required structural integrity.The research and development team at [Company Name] has been instrumental in sourcing and experimenting with various eco-friendly materials. They have successfully created boards that are not only strong and reliable but also have a significantly reduced carbon footprint. This development aligns with the global efforts to combat climate change and reduces dependence on fossil fuel-derived products.Section 3: Innovation 2 - Smart Technology Integration (200 words)In an era where connectivity and automation are rapidly reshaping industries, [Company Name] has harnessed the power of smart technology to bring innovation to its products. By integrating cutting-edge sensors, they have created "smart boards" that offer real-time data monitoring and analysis. These sensors can detect changes in temperature, humidity, and structural integrity, providing invaluable insights to users.This groundbreaking technology enables quicker identification of potential issues during construction or manufacturing processes, ensuring that boards meet the highest safety standards. Moreover, the data collected by these smart boards can be analyzed to optimize performance and predict maintenance needs, saving both time and resources. This integration of smart technology showcases [Company Name]'s commitment to providing its customers with state-of-the-art products that enhance efficiency and productivity.Section 4: Innovation 3 - Customization and Design Flexibility (200 words)Recognizing the need for personalized solutions in diverse industries, [Company Name] has developed an advanced customization platform. This platform allows clients to select from a wide range of sizes, finishes, and specialized features, tailored to their specific requirements. Through this initiative, the company empowers customers to bring their vision to life while ensuring optimal functionality and aesthetic appeal.The customization platform enhances design flexibility, enabling professionals in various fields such as architecture, interior design, and furniture manufacturing to create truly unique projects. [Company Name]'s cutting-edge manufacturing capabilities ensure that each customized order is promptly fulfilled without compromising on quality or durability.Conclusion (100 words)[Company Name] continues to captivate the industry with its commitment to innovation, sustainability, and customer-centric approaches. The company's introduction of advanced sustainable materials, smart technology integration, and enhanced customization options signifies their dedication to meeting evolving market demands. By combining their engineering expertise with sound environmental practices, [Company Name] remains a pioneer in the board manufacturing sector, promising a future where quality, sustainability, and innovation coexist seamlessly.Overall Word Count: 800 words.

High-Quality Melamine MDF Board: A Durable and Affordable Option for Your Projects

{Company Name} is revolutionizing the furniture industry with its innovative and eco-friendly products. The company specializes in the production of high-quality melamine MDF boards, which are versatile and durable materials used in various furniture applications. With a commitment to sustainability and quality, {Company Name} has become a trusted name in the industry.Melamine MDF boards are manufactured using a combination of wood fibers and resin, which are then coated with a decorative paper that is treated with melamine resin. The result is a smooth and durable surface that is resistant to scratches, moisture, and heat. This makes melamine MDF boards an ideal choice for kitchen cabinets, shelves, wardrobes, and other furniture items that require a combination of aesthetics and functionality.One of the key advantages of {Company Name}'s melamine MDF boards is their eco-friendly nature. The company uses sustainable wood sources and environmentally friendly production processes to minimize its impact on the environment. As a result, {Company Name} has earned certifications and accolades for its commitment to sustainability, making it a preferred choice for environmentally conscious consumers and businesses.In addition to their environmental benefits, {Company Name}'s melamine MDF boards are also known for their versatility. They are available in a wide range of designs, colors, and finishes, allowing designers and furniture manufacturers to create custom pieces that meet their clients' unique requirements. The boards can also be easily cut, shaped, and drilled, making them suitable for a variety of carpentry and woodworking projects.{Company Name} takes pride in its state-of-the-art manufacturing facilities and a team of skilled professionals who ensure that each melamine MDF board meets the highest quality standards. The company's commitment to excellence has earned it a reputation for reliability and consistency, with products that are known for their durability and long-lasting performance.As the demand for sustainable and durable furniture materials continues to grow, {Company Name} is well-positioned to meet the needs of the market. The company's melamine MDF boards have gained popularity among furniture manufacturers, interior designers, and homeowners who value quality, aesthetics, and environmental consciousness.In conclusion, {Company Name} is a leading manufacturer of melamine MDF boards, offering innovative and sustainable solutions for the furniture industry. With a focus on quality, sustainability, and versatility, the company has established itself as a trusted provider of eco-friendly materials that meet the diverse needs of its customers. As the industry continues to evolve, {Company Name} remains committed to driving innovation and setting new standards for excellence in the manufacturing of melamine MDF boards.

Benefits and Uses of High-Quality Formwork Plywood: A Comprehensive Guide

Title: Leading Plywood Manufacturer Introduces Innovative Formwork Plywood for Efficient ConstructionIntroduction:In line with its commitment to providing high-quality construction materials, a leading plywood manufacturer has recently unveiled its innovative Formwork Plywood solution. With a rich heritage in delivering superior plywood products, this company has once again raised the bar by introducing a formwork plywood that promises to revolutionize the construction industry. This versatile and durable material is set to enhance construction efficiency by ensuring consistent performance and cost-effectiveness.Body:1. Understanding Formwork Plywood:Formwork plywood is an essential component in modern construction, used to create molds or molds known as formwork for concrete structures. It provides temporary support during the construction process, enabling the desired shape and design of various concrete elements, such as columns, beams, slabs, and walls, to be achieved. The quality and durability of formwork plywood are crucial to ensuring the structural integrity and overall success of a construction project.2. The Enhanced Features of the New Formwork Plywood:The new formwork plywood from our featured manufacturer offers several enhanced features that separate it from traditional plywood options:a) Superior Strength and Durability:Utilizing the latest manufacturing techniques and advanced quality control, this formwork plywood exhibits remarkable strength and durability. It can withstand the constant pressure exerted by wet concrete and maintain its shape, integrity, and load-bearing capacity.b) Moisture Resistance:The new formwork plywood is designed to resist moisture, preventing warping, delamination, or any other damage during the concrete curing process. This ensures the strength and stability of the formwork structure remain intact, even in adverse environmental conditions.c) Smooth Surface Finish:Formwork plywood surfaces must be smooth to ensure a high-quality concrete finish. The company's new product promises an exceptionally smooth finish, reducing the need for additional surface treatments or alterations.d) Easy Handling and Assembly:The formwork plywood panels come in suitable sizes and are lightweight, making their handling and assembly more convenient and efficient. This feature aids in the rapid installation and removal of the formwork system, saving time and labor costs for construction projects.3. Commitment to Sustainability:Our leading plywood manufacturer is at the forefront of sustainable practices. Recognizing the importance of responsible forestry management, this company ensures that all its plywood products, including the new formwork plywood, are sourced from sustainably managed forests. With a commitment to reducing environmental impact, they prioritize the use of renewable materials and adhere to strict industry standards.4. Success Stories and Testimonials:Since the introduction of the new formwork plywood, several notable construction projects have successfully utilized this innovative product. Construction companies have praised its ease of use, durability, and cost-effectiveness, contributing to the completion of their projects on time and within budget. Testimonials from satisfied customers highlight the increased efficiency and reduced construction time achieved with this revolutionary formwork plywood.5. Expanding Reach and Collaborations:With its reputation for producing top-quality plywood products, our featured manufacturer is reaching new horizons. It actively collaborates with leading architects, engineers, and construction companies to research, develop, and improve its range of construction materials continually. The goal is to meet the evolving demands of the industry and provide innovative solutions that simplify construction processes for everyone involved.Conclusion:Introducing an advanced formwork plywood has solidified our leading plywood manufacturer's status as a reliable provider of high-quality construction materials. The enhanced features and sustainable sourcing of this innovative product make it an attractive choice for architects, engineers, and construction companies worldwide. By offering a combination of strength, durability, ease of use, and cost-effectiveness, this formwork plywood is destined to reshape the construction industry, streamline processes, and contribute to the efficient completion of diverse construction projects.

Strong and Durable Plywood: The Ideal Material for All Your Woodworking Needs

Title: Sustainable and Versatile Oak Plywood: The Ideal Solution for Modern Construction ProjectsIntroduction:In an era where sustainable practices are increasingly valued and demanded, the oak plywood industry is attaining new heights as a cornerstone of modern construction projects. Offering a superior combination of durability, aesthetic appeal, and environmental consciousness, this versatile material has gained immense popularity among architects, interior designers, and builders alike. Amidst this sea of options, one company stands out as a leading manufacturer of high-quality oak plywood, offering a diverse range of products that cater to the diverse needs of a rapidly evolving global market.Company Overview: [Company Name][Company Name], a pioneer in the oak plywood industry, has been revolutionizing the construction materials landscape since its inception. With a rich heritage and a commitment to sustainability, this company has firmly established its reputation as a reliable supplier of premium oak plywood products. Its state-of-the-art manufacturing facilities utilize cutting-edge technology to produce plywood that exceeds the industry's highest standards. Furthermore, [Company Name] is dedicated to responsible forest management, ensuring that its raw materials are sourced from sustainable and certified forests.Quality Assurance:[Company Name] prides itself on delivering oak plywood of uncompromising quality. Their adherence to strict manufacturing procedures, coupled with rigorous quality control measures, guarantees that every product meets or surpasses international standards. Prioritizing customer satisfaction, the company ensures that its plywood is consistent in strength, stability, and resistance to moisture. Each sheet undergoes thorough testing to ensure it lives up to its reputation as a premium building material, earning the trust of architects, designers, and builders worldwide.Diverse Product Range:Recognizing the need for tailored solutions to meet varied construction requirements, [Company Name] offers a diverse portfolio of oak plywood products. Whether it's for residential, commercial, or industrial purposes, their broad range of options caters to the diverse needs of their clientele. From high-density overlay plywood for concrete forming to fire-retardant plywood for enhanced safety, their offerings are designed to meet the demands of a rapidly changing construction industry. The company also provides custom services, allowing clients to select specific dimensions and finishes, further enhancing the flexibility and versatility of their products.Environmental Commitment:As environmental concerns take center stage, [Company Name] is at the forefront of sustainability efforts in the oak plywood sector. The company actively promotes responsible forest management practices and emphasizes the importance of utilizing certified, sustainably sourced timber. By adopting environmentally friendly manufacturing processes, such as incorporating renewable energy into operations and minimizing waste generation, [Company Name] provides eco-conscious individuals and organizations with a choice that aligns with their values.Market Impact and Global Reach:The oak plywood produced by [Company Name] has made a significant impact in both domestic and international markets. With an extensive distribution network, their products are readily available to customers across the globe. The company's commitment to delivering exceptional customer service, coupled with an unwavering dedication to quality, has garnered them a loyal and growing customer base. By continually expanding their range of products and offering competitive pricing, [Company Name] has established itself as an industry leader, driving innovation and setting new benchmarks for excellence.Conclusion:With its remarkable durability, aesthetic appeal, and commitment to sustainability, oak plywood has emerged as the material of choice for modern construction projects. [Company Name], a reputed manufacturer in this space, has positioned itself as a leading provider of premium oak plywood, catering to diverse project requirements. By prioritizing quality, sustainability, and customization, [Company Name] is successfully shaping the future of the construction industry and inspiring others to prioritize eco-conscious building materials.