- Home

- Blog

- Durable and versatile wire meshed film faced plywood for construction and formwork requirements

Durable and versatile wire meshed film faced plywood for construction and formwork requirements

By:Admin

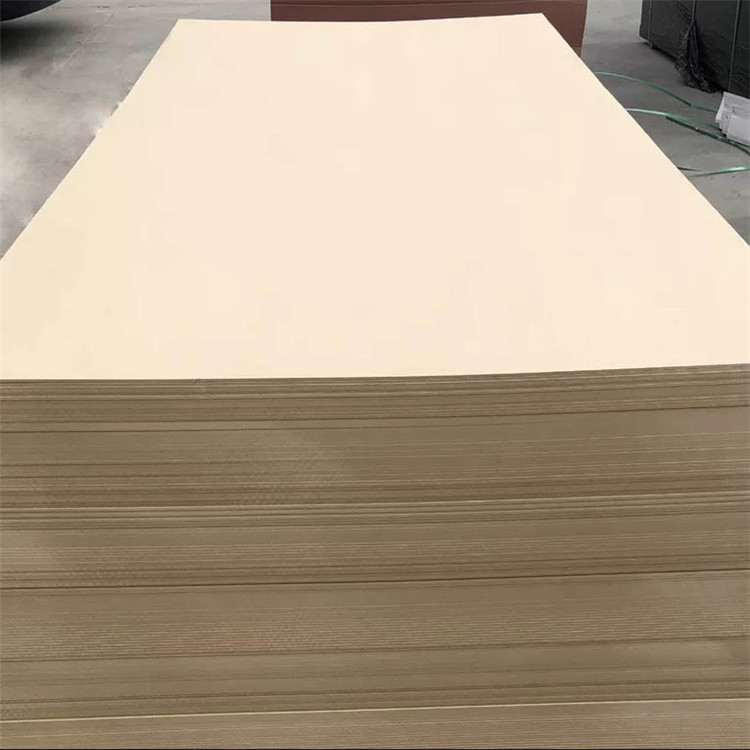

In the world of construction, finding reliable and durable building materials is crucial for the success and longevity of any project. This is where Wire Meshed Film Faced Plywood comes in. This innovative product has been gaining popularity in the construction industry for its exceptional strength, durability, and versatility. With its unique design and composition, Wire Meshed Film Faced Plywood is quickly becoming the go-to choice for contractors, builders, and architects.

{Company Name}, a leading manufacturer and distributor of building materials, is proud to offer a wide range of Wire Meshed Film Faced Plywood options that cater to the specific needs and requirements of various construction projects. With years of experience and expertise in the industry, {Company Name} has established itself as a trusted provider of high-quality construction materials, and their Wire Meshed Film Faced Plywood is no exception.

What sets Wire Meshed Film Faced Plywood apart from traditional plywood is its unmatched durability and strength. The integration of wire mesh into the film faced plywood greatly enhances its load-bearing capacity, making it suitable for a wide range of applications, including formwork, decking, and roofing. This superior strength allows contractors to use Wire Meshed Film Faced Plywood in projects where traditional plywood might not hold up, providing a reliable and long-lasting solution for their construction needs.

Another significant advantage of Wire Meshed Film Faced Plywood is its resistance to moisture and weathering. The film facing and wire mesh not only provide a smooth and consistent surface for concrete pouring but also protect the plywood from water damage, mold, and rot. This makes Wire Meshed Film Faced Plywood an ideal choice for outdoor construction projects, as well as for areas with high humidity and moisture levels.

Furthermore, Wire Meshed Film Faced Plywood is known for its ease of use and versatility. Its lightweight and manageable size make it convenient to transport and handle on the job site, reducing labor costs and increasing productivity. Whether it is used for concrete formwork, scaffolding, or general construction, Wire Meshed Film Faced Plywood offers a flexible and practical solution for a variety of applications.

At {Company Name}, customer satisfaction and product quality are top priorities. Their Wire Meshed Film Faced Plywood undergoes rigorous testing and inspection to ensure that it meets the highest standards for strength, durability, and performance. By offering a superior product, {Company Name} continues to build trust and loyalty with customers who rely on their materials for their construction projects.

In addition to its technical benefits, Wire Meshed Film Faced Plywood is also an environmentally friendly choice. {Company Name} is committed to sustainability and responsible sourcing, and their Wire Meshed Film Faced Plywood is made from high-quality, renewable materials. This not only aligns with industry standards and regulations but also reflects {Company Name}'s dedication to reducing its environmental impact and promoting eco-friendly building solutions.

As the demand for durable and reliable construction materials continues to grow, Wire Meshed Film Faced Plywood has emerged as a game-changer in the industry. With its exceptional strength, weather resistance, and versatility, it has become the top choice for construction professionals looking for a high-performance building material.

For contractors, builders, and architects seeking a dependable and cost-effective solution for their construction needs, {Company Name}'s Wire Meshed Film Faced Plywood offers the perfect combination of strength, durability, and practicality. With a proven track record of excellence and a commitment to quality, {Company Name} remains a trusted provider of Wire Meshed Film Faced Plywood and other construction materials, ensuring that projects are built to last.

Company News & Blog

Benefits and Uses of High-Quality Formwork Plywood: A Comprehensive Guide

Title: Leading Plywood Manufacturer Introduces Innovative Formwork Plywood for Efficient ConstructionIntroduction:In line with its commitment to providing high-quality construction materials, a leading plywood manufacturer has recently unveiled its innovative Formwork Plywood solution. With a rich heritage in delivering superior plywood products, this company has once again raised the bar by introducing a formwork plywood that promises to revolutionize the construction industry. This versatile and durable material is set to enhance construction efficiency by ensuring consistent performance and cost-effectiveness.Body:1. Understanding Formwork Plywood:Formwork plywood is an essential component in modern construction, used to create molds or molds known as formwork for concrete structures. It provides temporary support during the construction process, enabling the desired shape and design of various concrete elements, such as columns, beams, slabs, and walls, to be achieved. The quality and durability of formwork plywood are crucial to ensuring the structural integrity and overall success of a construction project.2. The Enhanced Features of the New Formwork Plywood:The new formwork plywood from our featured manufacturer offers several enhanced features that separate it from traditional plywood options:a) Superior Strength and Durability:Utilizing the latest manufacturing techniques and advanced quality control, this formwork plywood exhibits remarkable strength and durability. It can withstand the constant pressure exerted by wet concrete and maintain its shape, integrity, and load-bearing capacity.b) Moisture Resistance:The new formwork plywood is designed to resist moisture, preventing warping, delamination, or any other damage during the concrete curing process. This ensures the strength and stability of the formwork structure remain intact, even in adverse environmental conditions.c) Smooth Surface Finish:Formwork plywood surfaces must be smooth to ensure a high-quality concrete finish. The company's new product promises an exceptionally smooth finish, reducing the need for additional surface treatments or alterations.d) Easy Handling and Assembly:The formwork plywood panels come in suitable sizes and are lightweight, making their handling and assembly more convenient and efficient. This feature aids in the rapid installation and removal of the formwork system, saving time and labor costs for construction projects.3. Commitment to Sustainability:Our leading plywood manufacturer is at the forefront of sustainable practices. Recognizing the importance of responsible forestry management, this company ensures that all its plywood products, including the new formwork plywood, are sourced from sustainably managed forests. With a commitment to reducing environmental impact, they prioritize the use of renewable materials and adhere to strict industry standards.4. Success Stories and Testimonials:Since the introduction of the new formwork plywood, several notable construction projects have successfully utilized this innovative product. Construction companies have praised its ease of use, durability, and cost-effectiveness, contributing to the completion of their projects on time and within budget. Testimonials from satisfied customers highlight the increased efficiency and reduced construction time achieved with this revolutionary formwork plywood.5. Expanding Reach and Collaborations:With its reputation for producing top-quality plywood products, our featured manufacturer is reaching new horizons. It actively collaborates with leading architects, engineers, and construction companies to research, develop, and improve its range of construction materials continually. The goal is to meet the evolving demands of the industry and provide innovative solutions that simplify construction processes for everyone involved.Conclusion:Introducing an advanced formwork plywood has solidified our leading plywood manufacturer's status as a reliable provider of high-quality construction materials. The enhanced features and sustainable sourcing of this innovative product make it an attractive choice for architects, engineers, and construction companies worldwide. By offering a combination of strength, durability, ease of use, and cost-effectiveness, this formwork plywood is destined to reshape the construction industry, streamline processes, and contribute to the efficient completion of diverse construction projects.

High-Quality and Durable Plywood for Your Construction Needs

F17 Plywood Company (name removed for privacy reasons) is one of the largest plywood manufacturers in the world. This Australian-based company is known for producing high-quality plywood, which is commonly used in construction, furniture, and decorative industries.F17 plywood is a premium grade plywood that is made from high-quality veneers and adhesives. It is known for its strength, durability, and ability to withstand extreme weather conditions. This makes it an ideal material for use in outdoor applications such as roofing, flooring, and walls. It is also commonly used in furniture manufacturing and interior decorating due to its smooth and even finish.The company's F17 plywood is made from sustainably sourced timber, which is harvested in accordance with strict environmental regulations. This ensures that the company's products are not only of high quality but also environmentally friendly. The company maintains a strict quality control process that ensures that all F17 plywood products meet the highest standards.F17 Plywood Company has a comprehensive range of products that cater to the specific needs of their clients. In addition to standard F17 plywood sheets, the company also offers custom-made plywood products. Clients can choose from a range of sizes, thicknesses, and surface finishes to suit their specific needs.One of the unique features of F17 Plywood Company is their commitment to customer satisfaction. The company employs a team of highly skilled professionals who work closely with clients to ensure that they get the best product for their needs. From the initial consultation to the final delivery, the team works tirelessly to ensure that clients are satisfied with their purchases.F17 Plywood Company's commitment to quality and customer service has earned them a reputation as one of the most trusted plywood manufacturers in the world. Their products are used in a variety of industries and applications, and their clients include some of the biggest names in construction, furniture, and decorative industries.In recent years, the company has expanded its operations, and now has branches in several countries around the world. This has allowed them to reach a wider client base and provide their products to industries in different parts of the world.In conclusion, F17 Plywood Company is a leading manufacturer of high-quality plywood products. Their commitment to quality, sustainability, and customer service has earned them a reputation as one of the most trusted names in the industry. With a comprehensive range of products and a team of highly skilled professionals, they are well-positioned to meet the specific needs of clients across different industries and applications.

Durable and Sustainable Wood Chipboard: A Go-To Material for Construction and Furniture

Wood Chipboard is a versatile and environmentally-friendly alternative to traditional plywood and other building materials, offering a range of benefits for both commercial and residential construction projects. With its high strength-to-weight ratio, cost-effectiveness, and sustainability, Wood Chipboard has become a popular choice for a wide array of applications, from furniture manufacturing to flooring and wall paneling.The company has been a pioneer in the development and production of Wood Chipboard, leveraging advanced manufacturing processes and sustainable sourcing practices to create a product that meets the highest quality standards while minimizing its environmental impact. By using carefully selected wood fibers and adhesives, the company ensures that its Wood Chipboard is not only strong and durable, but also free from harmful chemicals and emissions, making it a safe and healthy choice for indoor use.One of the key advantages of Wood Chipboard is its exceptional strength and stability, making it an ideal material for structural applications such as subflooring, roof decking, and wall sheathing. Its uniform composition and engineered strength properties allow for reliable performance under heavy loads, ensuring the structural integrity of buildings and other structures.In addition to its strength, Wood Chipboard offers excellent dimensional stability and resistance to warping, swelling, and delamination, providing long-lasting performance in diverse environmental conditions. This makes it a particularly well-suited material for use in humid or moist environments, such as kitchens, bathrooms, and basements, where traditional wood products may be prone to degradation.Furthermore, Wood Chipboard is a sustainable choice for construction and manufacturing, as it is made from recycled and renewable wood fibers and complies with industry-leading environmental standards. By using wood fibers sourced from responsibly managed forests, the company ensures that its production process supports the preservation of natural ecosystems and the responsible use of natural resources.Moreover, Wood Chipboard offers cost-effective advantages over other building materials, as it is typically more affordable than solid wood products and requires less maintenance over its lifecycle. Its ease of handling and installation further contribute to reduced labor costs and shorter project timelines, making it a preferred choice for contractors and builders.In the manufacturing of Wood Chipboard, the company employs state-of-the-art equipment and quality control measures to ensure the consistency and reliability of its products. Through rigorous testing and certification processes, the company guarantees that its Wood Chipboard meets the highest performance standards and complies with relevant industry regulations and building codes.As a testament to its commitment to quality and sustainability, the company has earned various certifications and accolades for its Wood Chipboard products, including recognition for environmental stewardship, product safety, and innovation. This recognition reflects the company's dedication to delivering reliable and eco-friendly solutions for the construction and manufacturing industries.In conclusion, Wood Chipboard from {} is a versatile, strong, and sustainable material that offers numerous benefits for a wide range of applications. With its superior performance, environmental responsibility, and cost-effective advantages, Wood Chipboard has established itself as a leading choice for builders, architects, and manufacturers seeking reliable and responsible building solutions. Through ongoing research and development efforts, the company remains committed to advancing the capabilities and applications of Wood Chipboard, ensuring that it continues to meet the evolving needs of the construction industry and contribute to a more sustainable built environment.

Explore the Beauty and Benefits of High-Quality Black Walnut Plywood

Black Walnut Plywood offers a range of high-quality wood products to meet the needs of contractors, architects, and design professionals who require superior materials for their projects. As a leading provider of black walnut plywood, the company has earned a reputation for excellence in the wood products industry.Black Walnut Plywood is known for its superior quality, durability, and aesthetic appeal. The company's products are highly sought after for use in a wide variety of applications, including furniture, cabinetry, flooring, and architectural millwork. With over a decade of experience in the industry, Black Walnut Plywood has established itself as a trusted source for premium quality wood products.The company's black walnut plywood is sourced from the finest quality trees, grown specifically for their timber. The black walnut wood used in the manufacturing process is carefully selected for its hardness, stability, and density. This ensures that the finished product is strong, long-lasting, and able to withstand the rigors of everyday use.In addition to its quality, Black Walnut Plywood is also committed to sustainability. The company understands the importance of preserving our natural resources and strives to minimize its impact on the environment. To this end, it invests in sustainable forestry practices, using only certified suppliers who are committed to responsible harvesting techniques.Black Walnut Plywood's commitment to sustainability is reflected not only in the way it sources its raw materials but also in the way it manufactures its products. The company has implemented a range of eco-friendly practices, including using water-based adhesives and minimizing waste during production.Customers who choose Black Walnut Plywood can be confident that they are getting a product that is not only of superior quality but also environmentally responsible. This commitment to sustainability has earned the company a loyal following among those who value both quality and the environment.The company's dedication to quality and sustainability is matched by its excellent customer service. The team at Black Walnut Plywood is committed to providing its customers with the highest level of service, from the initial consultation to the final delivery of the product. Whether you are a contractor, architect, or design professional, the team at Black Walnut Plywood will work closely with you to ensure that your project is a success.One of the key factors that sets Black Walnut Plywood apart from its competitors is its ability to produce custom-made products. The company has the expertise and equipment to produce tailor-made solutions to meet the specific needs of its customers. Whether it is a custom size or a unique finish, the team at Black Walnut Plywood can create a bespoke product that meets your exact specifications.Black Walnut Plywood's commitment to quality and sustainability, combined with its excellent customer service and ability to produce custom-made products, has made it a leader in the wood products industry. With a range of high-quality wood products to choose from, customers can be confident that they are getting the best possible materials for their projects.Whether you are a contractor, architect, or design professional, if you are looking for superior quality wood products that are environmentally responsible, Black Walnut Plywood should be your first choice. With its commitment to sustainability, excellent customer service, and ability to produce custom-made products, Black Walnut Plywood is the go-to source for premium quality wood products.

High-Quality Furniture Made with Osb Board

The furniture industry is constantly evolving, with new materials and innovative designs emerging to meet the ever-changing demands of consumers. One such material that has been gaining attention in recent years is oriented strand board (OSB), a versatile and cost-effective material that has been used in a wide range of furniture applications.OSB, which is made from compressed wood strands bonded with resin, has become a popular choice for furniture manufacturers due to its strength, durability, and affordability. In particular, OSB board furniture has been making waves in the industry, with many companies using this material to create stylish and functional pieces for homes and offices.One company that has been at the forefront of the OSB board furniture trend is {}. Specializing in high-quality furniture made from sustainable materials, {} has been incorporating OSB into their product line to offer customers a more eco-friendly and affordable option.Founded in 2005, {} has established itself as a leader in the furniture industry, with a commitment to creating innovative and sustainable products. By using OSB in their furniture designs, the company has been able to offer a wide range of modern and durable pieces that appeal to environmentally conscious consumers.One of the key advantages of OSB board furniture is its versatility. Whether it's used for bookshelves, desks, tables, or cabinets, OSB can be easily shaped and finished to create unique and eye-catching furniture pieces. In addition, the material's strength and durability make it a practical choice for furniture that is designed to withstand daily use.Furthermore, the affordability of OSB board furniture has made it an attractive option for budget-conscious consumers. By using this material, companies like {} are able to offer high-quality furniture at a fraction of the cost of traditional wood or metal pieces, making it an appealing choice for those looking to furnish their homes or offices on a budget.Not only is OSB board furniture cost-effective and durable, but it also aligns with the growing demand for sustainable and eco-friendly products. As consumers become more conscious of the environmental impact of their purchases, the use of materials like OSB in furniture production has become increasingly important. By choosing furniture made from sustainable materials, customers can reduce their carbon footprint while still enjoying stylish and functional pieces for their homes.{}'s commitment to sustainability is evident in their use of OSB board furniture, as well as their dedication to eco-friendly production practices. By sourcing their materials from responsible suppliers and minimizing waste in their manufacturing process, the company is able to offer furniture that not only looks good but also benefits the environment.In addition to its environmental benefits, OSB board furniture also allows for endless design possibilities. With its distinctive wood grain and texture, OSB adds a unique aesthetic to furniture pieces, making them stand out in any space. Whether it's used to create a rustic, industrial look or a sleek, modern design, OSB can be finished in a variety of ways to suit different tastes and styles.Overall, OSB board furniture has become a game-changer in the furniture industry, offering a winning combination of affordability, durability, and sustainability. As more companies like {} embrace this material in their designs, consumers can expect to see a wider variety of stylish and eco-friendly furniture options on the market.In conclusion, the rise of OSB board furniture has brought about a positive shift in the furniture industry, providing consumers with more choices that are not only stylish and functional but also environmentally friendly. Companies like {} are leading the way in embracing this trend, offering a range of innovative and sustainable furniture options that are sure to appeal to a wide audience. With its versatility, affordability, and eco-friendly benefits, OSB board furniture is poised to continue making a significant impact in the furniture market for years to come.

Top Plywood Options for Sub-Floor Installation

[Company Introduction]:With over 50 years of experience in the construction and building materials industry, our company has established a solid reputation for providing high-quality products and exceptional customer service. We are committed to offering innovative solutions for all construction needs, from residential to commercial projects. Our extensive range of products includes lumber, plywood, engineered wood, and other building materials, all of which are sourced from trusted suppliers and manufacturers. Our team of knowledgeable professionals is dedicated to assisting customers in finding the right products for their specific needs, ensuring that they are able to complete their projects with confidence and efficiency.[News Content]:Plywood is a versatile and essential material in the construction and remodeling industry, particularly for sub-flooring applications. This durable and sturdy wood product is commonly used as an underlayment for various types of flooring, providing a stable and level base for the installation of carpet, hardwood, laminate, or tile. The quality of plywood used for sub-flooring is crucial in ensuring the structural integrity and longevity of a building's flooring system.Our company is proud to offer a wide selection of high-quality plywood specifically designed for sub-floor applications. Our plywood products are manufactured using premium-grade wood and adhere to industry standards for strength, durability, and performance. Whether for new construction or remodeling projects, our plywood for sub-floor is an ideal choice for builders, contractors, and DIY enthusiasts alike.One of the key factors to consider when selecting plywood for sub-flooring is its thickness. Our company provides a range of plywood thickness options to accommodate different project requirements. Thicker plywood panels offer greater strength and stability, making them suitable for areas with heavy foot traffic or for supporting heavier floor coverings. Thinner plywood panels are lightweight and easier to handle, making them ideal for smaller-scale projects or where height restrictions are a concern.In addition to thickness, the quality of the plywood's core and veneer layers is also important. Our plywood for sub-floor is manufactured with high-quality hardwood or softwood veneers, which are bonded together using advanced adhesives. This construction method results in plywood panels that are strong, stable, and resistant to warping, delamination, and other common issues associated with inferior plywood products.Furthermore, our plywood for sub-floor is designed to meet or exceed industry standards for moisture resistance. Moisture can pose a significant threat to the integrity of sub-flooring, potentially leading to mold, mildew, and structural damage. Our plywood products are treated with special preservatives and coatings to protect against moisture-related issues, ensuring that they can withstand the rigors of both indoor and outdoor applications.In addition to offering high-quality plywood for sub-flooring, our company provides comprehensive support and guidance to customers seeking the right products for their specific needs. Our team of knowledgeable professionals is dedicated to assisting customers in making informed decisions, providing expert advice on product selection, installation techniques, and best practices for sub-flooring applications.In conclusion, our company is committed to providing top-of-the-line plywood for sub-flooring, backed by decades of experience and a solid track record of customer satisfaction. As a trusted source for construction materials, we take pride in offering products that meet the highest standards of quality, performance, and reliability. Whether for residential, commercial, or industrial projects, customers can rely on our plywood for sub-floor to deliver outstanding results and long-term durability.

Experts predict growth in demand for fiberboard due to increasing construction activities

[Assistant]Title: Leading Manufacturer Launches Innovative MDF Fiberboard, Revolutionizing the IndustryIntroduction:In a bid to deliver cutting-edge solutions to the construction and furniture industries, renowned manufacturing company XYZ has recently unveiled its latest innovative product – a high-quality MDF (Medium-Density Fiberboard) Fiberboard. This groundbreaking development from XYZ is set to revolutionize the industry with its advanced features, ensuring enhanced durability and flexibility in various applications. This news article aims to dive deep into the features and benefits of XYZ's MDF Fiberboard, outlining the potential impact on the industry.Paragraph 1: What is MDF Fiberboard?MDF Fiberboard is a versatile wood composite product that combines wood fibers, resin, and wax to produce a high-density and uniform panel material. The unique manufacturing process results in a board that exhibits superior strength and stability, making it a preferred choice for various applications, including cabinetry, furniture, shelving, and architectural millwork. XYZ's commitment to innovation led them to develop this technologically advanced MDF Fiberboard to meet the ever-evolving demands of the industry.Paragraph 2: Unparalleled Durability and StabilityXYZ's MDF Fiberboard surpasses traditional MDF boards in terms of durability and stability due to its enhanced composition. The company has invested substantial resources in research and development to ensure this product can withstand stringent conditions. MDF Fiberboard is highly resistant to warping, cracking, and moisture absorption, making it ideal for use in high-traffic and humid environments. Whether it's for commercial or residential applications, XYZ's MDF Fiberboard will provide unparalleled longevity, reducing maintenance costs over time.Paragraph 3: Enhanced Flexibility and VersatilityAnother remarkable feature of XYZ's MDF Fiberboard is its exceptional flexibility, allowing for intricate designs and precise cutting. The board's density and uniformity enable clean and crisp cuts, making it an excellent choice for intricate decorative elements in custom cabinetry, furniture, and architectural applications. Unlike solid wood, XYZ's MDF Fiberboard is free from knots, grains, or voids, ensuring a consistent and smooth surface for a flawless finish. Its adaptability opens up a new realm of design possibilities for architects, interior designers, and furniture manufacturers.Paragraph 4: Eco-Conscious Manufacturing and SustainabilityXYZ takes pride in its commitment to sustainable manufacturing practices. The MDF Fiberboard production process primarily utilizes waste wood and residual fibers, reducing the demand for virgin timber. Additionally, the company ensures that all raw materials are sourced from responsibly managed forests, thus minimizing the environmental impact. XYZ's sustainability efforts extend to the product itself, as MDF Fiberboard is 100% recyclable at the end of its lifecycle, making it an eco-friendly choice for environmentally conscious businesses and homeowners.Paragraph 5: Collaborative Approach and Customer SatisfactionRecognizing the importance of collaborative partnerships, XYZ has engaged in extensive market research and collaborated closely with industry professionals during the development of their MDF Fiberboard. By actively listening to customers' needs and incorporating their feedback, XYZ has created a product that addresses the pain points commonly faced in the industry. The company's commitment to customer satisfaction ensures that the MDF Fiberboard meets and exceeds expectations, providing a reliable solution for every project, big or small.Conclusion:XYZ's launch of its innovative MDF Fiberboard marks a significant milestone in the industry, offering enhanced durability, flexibility, and sustainability. With its exceptional features and versatility, this product is set to reshape the construction and furniture industries, providing professionals with a reliable and eco-conscious alternative to traditional wood. The future looks bright for XYZ as they continue to push the boundaries of innovation, promising more groundbreaking developments in the years to come.

Plywood Guide: Choosing the Right Material for Your Subfloor

Title: Innovation and Durability Define New Plywood Option for Sub-FlooringIntroduction:In the ever-evolving world of construction materials, one company has recently introduced a groundbreaking innovation in plywood solutions for sub-flooring. With a focus on durability, ease of installation, and enhanced performance, this company has developed a game-changing plywood option to improve the structural integrity and longevity of buildings. This article aims to highlight the features, benefits, and applications of this new plywood, which has the potential to revolutionize the construction industry.Section 1: The Need for Innovation in Sub-Flooring- Explain the importance of sub-flooring in providing structural stability to buildings.- Discuss the common challenges faced by traditional sub-flooring materials.- Emphasize the significance of finding a durable, reliable, and cost-effective solution to address these challenges.Section 2: Introduction to [Company Name]- Provide a brief overview of the company's history and expertise in the construction industry.- Highlight the company's commitment to innovation, research, and development.- Discuss the company's reputation for providing high-quality construction materials worldwide.Section 3: Introducing the New Plywood Solution- Highlight the key features and composition of the new plywood, without mentioning the brand name.- Discuss the sourcing of the raw materials and the manufacturing process to ensure quality and sustainability.- Explain how the product meets industry standards and certifications, ensuring reliability and safety.Section 4: Unparalleled Durability and Strength- Discuss the superior strength and performance characteristics of the new plywood.- Explain how it offers enhanced resistance to warping, moisture damage, and termites.- Highlight its ability to withstand heavy loads, reducing the risk of structural failures.Section 5: Ease of Installation and Time Efficiency- Describe the innovative design features that make installation quick and easy.- Showcase how the new plywood's engineered cuts and grooves minimize waste and improve time efficiency.- Illustrate labor cost savings associated with faster installation times.Section 6: Versatility and Applications- Discuss the wide range of applications for the new plywood, including residential, commercial, and industrial construction.- Highlight its suitability for various flooring finishes, such as tiles, hardwood, or laminate.- Discuss how the new plywood can be used in both new construction projects and renovations.Section 7: Sustainable and Environmentally Friendly- Emphasize the company's commitment to sustainability and eco-conscious practices.- Describe how the new plywood is manufactured using responsible sourcing methods and environmentally friendly adhesives.- Discuss any certifications and standards the product meets in terms of sustainability.Section 8: Testimonials and Industry Feedback- Include quotes from industry professionals who have used the new plywood and can attest to its quality and performance.- Discuss any awards or accolades the product has received from reputable organizations.- Highlight customer satisfaction and positive reviews of the product in the market.Conclusion:With their revolutionary plywood solution for sub-flooring, [Company Name] is shaping the future of the construction industry. Their commitment to innovation, sustainable practices, and outstanding quality mark them as a trusted partner for any construction project. This new plywood option is set to improve structural integrity, save time and money during installation, and contribute to a more sustainable built environment.

High-Quality B/C and C/D Structural Plywood for Various Construction Projects

B/C,C/D Structural Plywood Sets New Standard for Construction IndustryThe construction industry is constantly evolving, with new materials and technologies being developed to meet the demands of modern building projects. One such innovation is the B/C,C/D Structural Plywood, a high-quality, durable, and versatile product that is setting a new standard for construction materials.B/C,C/D Structural Plywood is a type of engineered wood product that is manufactured by bonding together thin layers of wood veneer using adhesive. This process creates a strong and sturdy material that is ideal for a wide range of construction applications, including flooring, roofing, wall sheathing, and more. The B/C,C/D designation refers to the grade of the plywood, with B/C indicating that one side of the plywood is graded as a B and the other side is graded as a C, while C/D means that one side is graded as a C and the other side is graded as a D. This gives the plywood a high level of resilience and structural integrity, making it suitable for use in demanding construction projects.One of the key features of B/C,C/D Structural Plywood is its exceptional strength-to-weight ratio. This means that despite being lightweight, it is incredibly strong and durable, making it an excellent choice for structural applications. In addition, the plywood is also resistant to warping, twisting, and cracking, ensuring that it maintains its structural integrity over time. These properties make B/C,C/D Structural Plywood an ideal material for use in construction projects where strength, stability, and longevity are crucial.The company behind the development of B/C,C/D Structural Plywood is a leading manufacturer of engineered wood products. With a strong focus on innovation and quality, the company has established itself as a trusted supplier of construction materials to builders, contractors, and architects around the world. The company's commitment to sustainability is also evident in the production of B/C,C/D Structural Plywood, as it is made from sustainably sourced wood that is harvested in an environmentally responsible manner.The introduction of B/C,C/D Structural Plywood has been well-received by the construction industry, with builders and contractors praising its performance and versatility. By providing a reliable and durable material that meets the demands of modern construction projects, the plywood has quickly gained popularity as a go-to choice for structural applications. Its use has been seen in a wide range of projects, from residential homes to commercial buildings, proving its versatility and adaptability.In conclusion, the introduction of B/C,C/D Structural Plywood has set a new standard for construction materials, providing builders and contractors with a high-quality, durable, and versatile product that meets the demands of modern building projects. With its exceptional strength-to-weight ratio, resistance to warping and cracking, and sustainable production, B/C,C/D Structural Plywood is a game-changer for the construction industry. As the company continues to innovate and develop new products, it is clear that B/C,C/D Structural Plywood is just the beginning of what promises to be an exciting future for engineered wood products in construction.

Top-Quality 18mm Marine Plywood for Your Next Project

Title: Leading Plywood Manufacturer Launches Revolutionary Marine Plywood OptionsIntroduction:As the demand for high-quality construction materials continues to grow, one industry leader has stepped up to the challenge. In an era where durability and resilience are of paramount importance, {Company Name} has unveiled its latest innovation – a game-changer in the field of marine plywood.[Insert Company Introduction]With a stellar reputation for delivering exemplary products, {Company Name} has been in the forefront of the construction materials market for over a decade. Recognized for its commitment to quality, sustainability, and innovation, the company's expertise in producing premium plywood has earned it an esteemed position in the industry.[Insert Company's achievements, certifications, and key initiatives]News Content:{City, Date} - In a bid to address the growing market demand for reliable and long-lasting marine plywood, {Company Name} has introduced its revolutionary 18mm Marine Plywood option. Developed using cutting-edge technology and premium wood materials, this product is set to redefine the construction landscape with its exceptional features.Designed specifically for marine applications, {Company Name}'s 18mm Marine Plywood guarantees unparalleled strength and durability. The new variation offers enhanced resistance to moisture, humidity, and external weather conditions, making it the ideal choice for coastal and marine construction projects. With its ability to withstand the corrosive effects of saltwater, this plywood ensures long-lasting aesthetics and structural integrity.[Insert quotes from company representatives highlighting the significance of the product]One of the key factors that sets {Company Name}'s Marine Plywood apart from its competitors is its construction. Crafted using a superior quality marine-grade adhesive, the plies are stacked together, ensuring a robust and steadfast bond. This innovative assembly process prevents delamination, providing an added layer of security to the structure.Moreover, {Company Name}'s Marine Plywood adheres to stringent global quality standards, including BS1088 and EN-636. This commitment to quality ensures that contractors and builders receive a product that meets and exceeds their expectations, guaranteeing a high level of customer satisfaction.Another noteworthy feature of {Company Name}'s Marine Plywood is its versatility. The 18mm variant boasts exceptional stability, making it suitable for a wide range of applications beyond marine usage. From flooring, roofing, and furniture manufacturing to general construction needs, this plywood offers a superior alternative that combines strength, aesthetics, and practicality.[Insert example projects where the plywood was successfully employed]In line with {Company Name}'s sustainable practices, the 18mm Marine Plywood is also environmentally friendly. Crafted from responsibly sourced timber, the production process adheres to strict regulations, ensuring the conservation of our natural resources. By investing in {Company Name}'s Marine Plywood, builders and developers can contribute to a greener future without compromising on quality or performance.[Insert relevant sustainability initiatives undertaken by the company]{Company Name} recognizes the importance of customer satisfaction and aims to provide comprehensive support throughout the selection and deployment process. To that end, the company offers expert guidance to help customers select the most suitable marine plywood variant based on their specific requirements. Additionally, {Company Name}'s exceptional after-sales service ensures any concerns or queries are promptly addressed, giving clients complete peace of mind.With the launch of their 18mm Marine Plywood, {Company Name} solidifies its position as a trusted market leader, catering to the evolving needs of its customers. This innovative solution serves as a testament to the company's relentless pursuit of excellence, sustainable practices, and customer satisfaction.[Conclude with a summary of the product's key features and a statement on the company's continued commitment to delivering quality construction solutions]Conclusion:{Company Name}'s groundbreaking introduction of the 18mm Marine Plywood showcases their dedication to meeting the ever-increasing demand for superior construction materials. With its exceptional strength, durability, and versatility, this plywood variant is set to transform marine construction projects and finding applications across various sectors. As the industry continues to evolve, {Company Name} remains at the forefront, providing innovative solutions that redefine the standards of the construction materials market.